Cleaner Air Oregon is a health-based permitting program that regulates emissions of toxic air contaminants from facilities based on risk to nearby communities. CAO requires facilities to report toxic air contaminant emissions, assess potential health risks to people nearby and reduce toxic air contaminant risk if it exceeds legal limits.

As part of the Cleaner Air Oregon process, each facility has a dedicated web page to provide communities access to facility information and updates on where it is involved in the process.

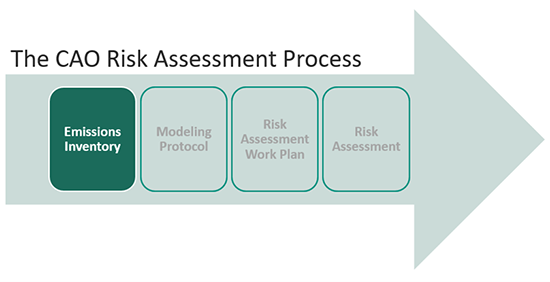

- Each step of the CAO risk assessment process has a section that includes DEQ's communications and deliverables from the facility.

- The graphic below shows where a facility is in the Cleaner Air Oregon Process.

For additional information and history of the program, visit the Cleaner Air Oregon website.

The Emissions Inventory provides information on all the Toxic Air Contaminant emissions from a facility, and includes information on a facility's operations and activities, as well as fuel and material usage rates. This is often the longest step in the CAO risk assessment process as DEQ needs to verify that all activities have been accounted for, and that the most representative emissions data available are used. In some cases, DEQ will require a facility to perform source testing at this stage if insufficient data is available to estimate emissions. For an introduction to emissions inventories and why they matter, please see EPA's Fact Sheet.

April 26, 2024: Facility Called In to CAO Program

June 12, 2024: Facility requests extension to conduct Source Testing

June 24, 2024: DEQ Responded to Facility

Sept. 5, 2024: Facility Requests Extension

Sept. 9, 2024: DEQ Responds to Extension Request

Nov. 7, 2024: Facility Requests Extension

Nov. 18, 2024: DEQ Responds to Extension Request

Dec. 20, 2024: Facility submitted an Emissions Inventory and supporting documentation (currently in DEQ review)

The Modeling Protocol provides information on how the facility plans to accurately model the concentrations of Toxic Air Contaminants (TACs) that community members may be exposed to based on the TAC emissions data from the approved Emissions Inventory. A Risk Assessment Work Plan is required for more complex Risk Assessments (Level 3 or Level 4) and provides more detailed information about locations where people live or normally congregate around the facility and how risk to these community members will be evaluated.

Dec. 20, 2024: Facility submitted a Modeling Protocol and Risk Assessment Work Plan (currently in DEQ review)

About the Facility

Biomass One, L.P. is an electrical generation facility using biomass as the fuel source in boilers that supply high pressure steam to turbines for power generation and sale to the electrical grid. The electric power cogeneration plant includes two biomass boilers that produce high pressure steam delivered to any of three turbines that can generate up to 30 Megawatts (MW) of electricity. The process includes the handling, processing, and storage of hogged fuel; a cooling tower; and a community biomass recycling center. Woody, organic material is purchased from the market or supplied by the community at a minimal dumping fee and is processed, chipped, and screened to be used as fuel for the boilers. The screened fractions from these processes and the boiler ash are combined into agricultural mulch and sold or disposed of as waste. The facility has been operating since 1986.