Cleaner Air Oregon is a health-based permitting program that regulates emissions of toxic air contaminants from facilities based on risk to nearby communities. CAO requires facilities to report toxic air contaminant emissions, assess potential health risks to people nearby and reduce toxic air contaminant risk if it exceeds legal limits.

As part of the Cleaner Air Oregon process, each facility has a dedicated web page to provide communities access to facility information and updates on where it is involved in the process.

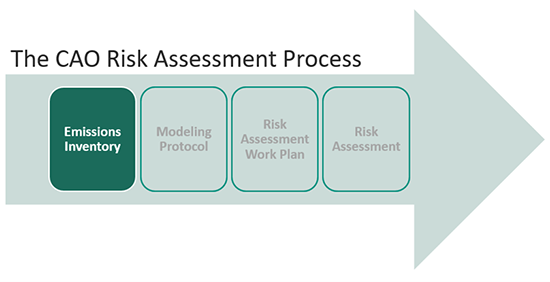

- Each step of the CAO risk assessment process has a section that includes DEQ's communications and deliverables from the facility.

- The graphic below shows where a facility is in the Cleaner Air Oregon Process.

For additional information and history of the program, visit the Cleaner Air Oregon web page.

The Emissions Inventory provides information on all the Toxic Air Contaminant emissions from a facility, and includes information on a facility’s operations and activities, as well as fuel and material usage rates. This is often the longest step in the CAO risk assessment process as DEQ needs to verify that all activities have been accounted for, and that the most representative emissions data available are used. In some cases, DEQ will require a facility to perform source testing at this stage if insufficient data is available to estimate emissions.

March 1, 2022: Facility called in to CAO program.

May 31, 2022: PCC-SSBO submits Emissions Inventory and supporting documentation (Under DEQ Review)

About the Facility

PCC SSBO operates a primarily non-ferrous alloy investment casting foundry referred to as the Small Structurals Business Operations (SSBO). The process includes the manufacture of a wax part pattern or replica of the finished product. The wax replica is repeatedly dipped into a slurry and coated with sand. Upon drying this forms a hard ceramic shell. The wax is then melted out of the ceramic shell and the shell is cured to create a mold for casting. Molten metal is then poured into the shell and upon cooling the shell is removed from the metal part by physical and chemical processes. The metal part goes through finishing processes including heat treating, grinding, abrasive blasting, and welding. The facility was built in 1979.